Floor Milling Machine RT-2500 Roto-Tiger

| Motor/ Power | 4 kW (Electric) /

7.2 HP (Gasoline) |

| Voltage | 400V |

| Working width | 250 mm |

| Weight | 129 – 136 kg |

SKU: RT-2500

Category: Scarifying - Milling

| Motor/ Power | 4 kW (Electric) /

7.2 HP (Gasoline) |

| Voltage | 400V |

| Working width | 250 mm |

| Weight | 129 – 136 kg |

The fast and strong Scarifier: Environmentally-friendly and in accordance with the required profile.

Runway marking removal at the Geneva Airport.

Concrete surfaces preparation – roughening.

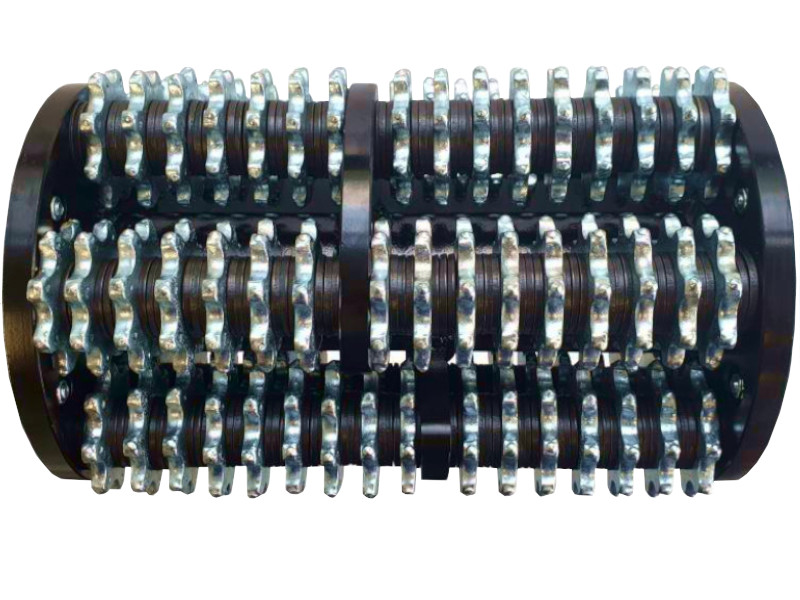

Cutters and milling wheels, loosely placed on a rotating work drum, thorough yet gentle rasping and milling off of adhesive, rubber, concrete slurry, uneven spots and old coatings. Continuous depth settings from fine to coarse. Wide range of tools for every purpose.

Article-No.: RT-2500-985-1

Article-No.: AT-999-940

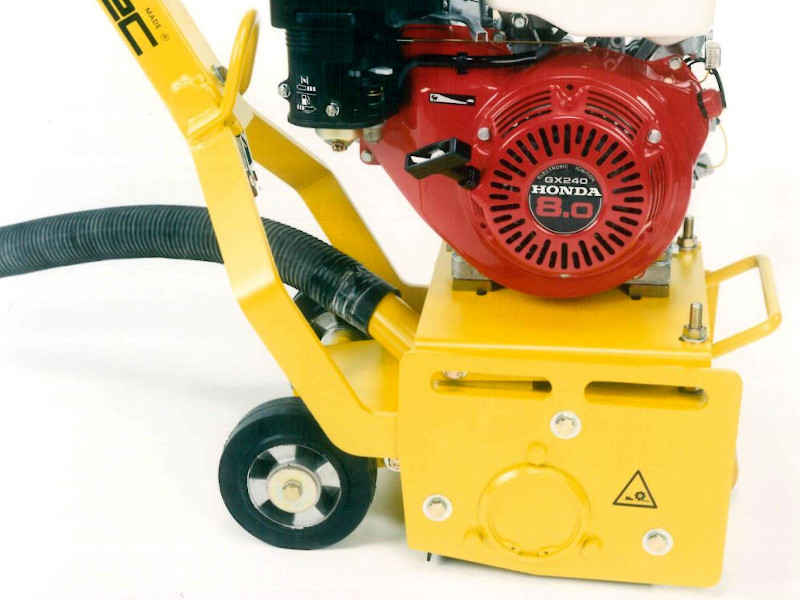

Schneider Electric motor with on/off button, emergency Stop function

Schneider Electric motor with on/off button, emergency Stop function

Drum lever for quick and controlled lift-off

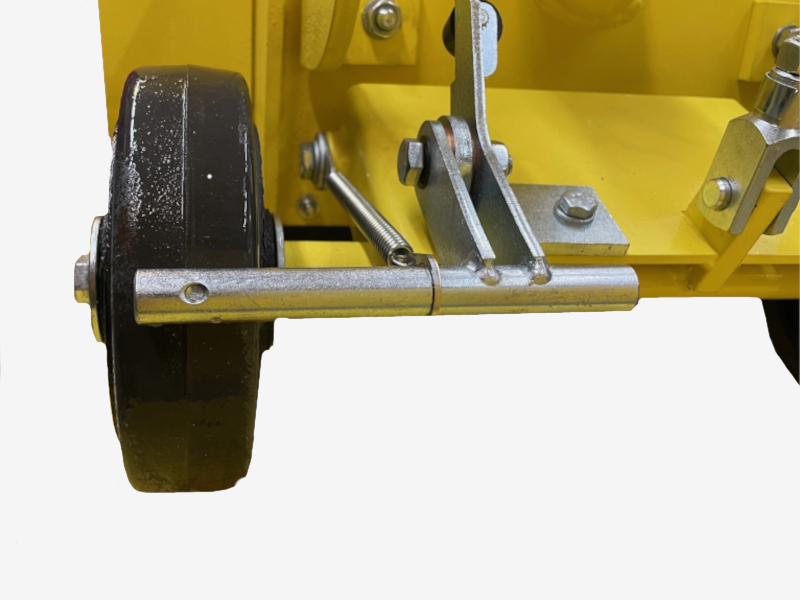

Adjustable milling depth

For a safe transport and good grip on sloping surfaces

Connection for industrial vacuum cleaner for low-dust work

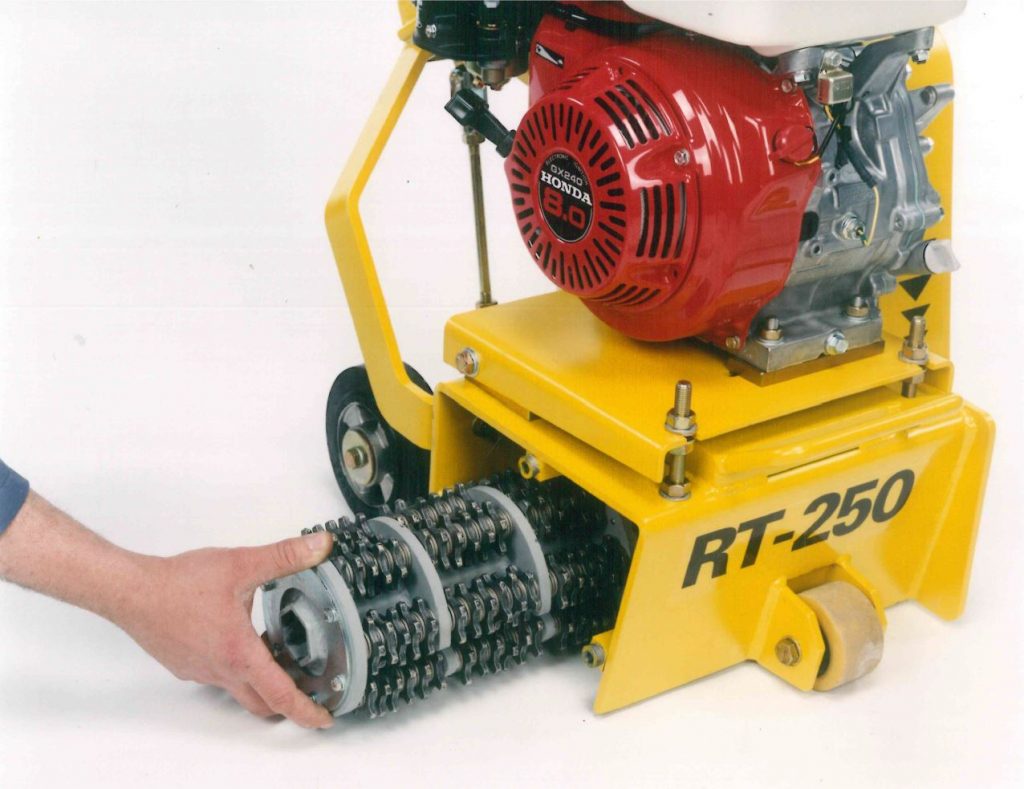

For a quick and effortless drum change on site

Mirror for high precision marking removal.

Grinding up to the edge with AIRTEC special Drum.

| Variations | Motor/ Power | Voltage |

| Standard 400V | 4 kW | 400V / 50 Hz / 16A / 3 Phases |

| Standard petrol engine | Honda Benzin | 7.2 PS |

| All Machines | |

| Working Width | 250 mm |

| Dimensions (L x W x H) | 1130 x 480 x 1180 mm |

| Weight | 129 – 136 kg |

| Suction Tube Ø | 38 mm / 51 mm Tube |

| Basic equipment | RT-2500-EL or RT-2500-B with 1 standard drum (RT-2500-985-1) |

| equipped with 1 Set HMT-8.55/20 and spacers | |

| 5 metre power cable and plug | |

| Hexagon spanner | |

| Operating manual and spare parts list | |

| Audit Log und Warranty Certificate |

| Option | 400 V, Gasoline |

|---|